Product manufacturing serves as the pivotal bridge between conceptualization and realization, transforming ideas into tangible goods that enrich our lives. This intricate process involves a series of steps, from design and prototyping to production and distribution, each contributing to the creation of high-quality, market-ready products. In this article, we delve into the multifaceted realm of product manufacturing, exploring its key components, challenges, and future prospects.

The Essence of Product Manufacturing:

Product manufacturing encompasses the systematic conversion of raw materials or components into finished goods through specialized processes and technologies. It involves a collaborative effort among designers, engineers, technicians, and production specialists to translate design specifications into functional, aesthetically pleasing products that meet consumer needs and preferences.

Key Components of Product Manufacturing:

- Product Design and Development: The manufacturing journey begins with product design and development, where designers and engineers conceptualize ideas, create prototypes, and refine product specifications. Advanced computer-aided design (CAD) software and rapid prototyping technologies enable designers to visualize and iterate designs with precision and efficiency.

- Material Sourcing and Procurement: Manufacturing relies on a diverse array of raw materials, components, and resources sourced from suppliers and vendors worldwide. Effective supply chain management is essential to ensure timely procurement, quality control, and cost optimization while minimizing risks associated with supply chain disruptions or fluctuations in raw material prices.

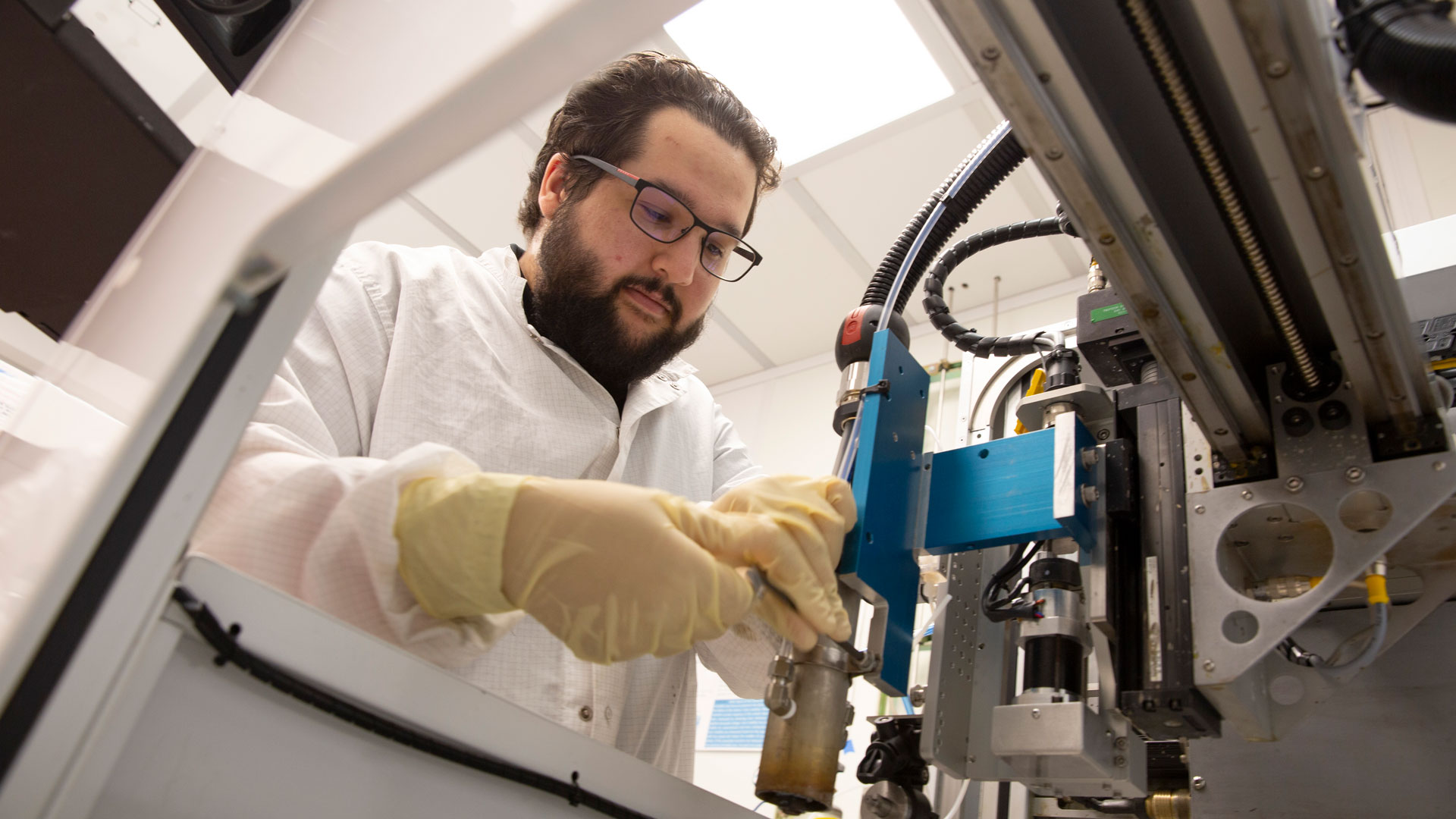

- Production Processes and Technologies: Product manufacturing encompasses a wide range of production processes and technologies tailored to specific industries and product requirements. These may include machining, casting, molding, welding, assembly, and finishing techniques, each optimized for efficiency, precision, and quality assurance.

- Quality Control and Assurance: Maintaining product quality and consistency is paramount in manufacturing to uphold brand reputation, meet regulatory standards, and ensure customer satisfaction. Quality control measures such as inspections, testing, and certifications are implemented throughout the production cycle to detect defects, deviations, and non-conformities.

- Logistics and Distribution: Once manufactured, products undergo packaging, labeling, and distribution processes to reach end consumers efficiently. Logistics management involves optimizing transportation routes, inventory storage, and order fulfillment to minimize lead times, reduce costs, and enhance customer service levels.

Challenges in Product Manufacturing:

Despite its importance, product manufacturing faces several challenges that impact efficiency, productivity, and competitiveness:

- Global Supply Chain Disruptions: The COVID-19 pandemic highlighted the vulnerabilities of global supply chains, leading to disruptions in production, logistics, and procurement. Manufacturers are reassessing supply chain strategies to mitigate risks, enhance resilience, and localize production capabilities.

- Technological Complexity: Rapid advancements in automation, robotics, and digitalization are reshaping manufacturing processes and skill requirements. Manufacturers must invest in workforce training, upskilling, and digital transformation initiatives to remain competitive in a rapidly evolving technological landscape.

- Sustainability Imperatives: Growing concerns about environmental sustainability and resource depletion are driving demand for eco-friendly manufacturing practices and materials. Manufacturers are embracing circular economy principles, renewable energy sources, and waste reduction strategies to minimize their environmental footprint and enhance sustainability credentials.

- Market Volatility and Consumer Dynamics: Fluctuations in consumer preferences, market trends, and geopolitical factors can impact demand forecasting, inventory management, and production planning. Manufacturers must adopt agile, responsive strategies to adapt to changing market dynamics and maintain market relevance.

Future Prospects of Product Manufacturing:

The future of product manufacturing is poised for innovation, resilience, and sustainability. Emerging technologies such as additive manufacturing, artificial intelligence, and the Internet of Things (IoT) are revolutionizing production processes, enabling greater customization, flexibility, and efficiency. Industry 4.0 initiatives, characterized by the integration of digital technologies and data-driven analytics, are driving the transformation of traditional manufacturing paradigms into smart, interconnected ecosystems.

Conclusion:

Product manufacturing is a dynamic and complex process that underpins economic growth, technological progress, and societal advancement. By embracing innovation, sustainability, and collaboration, manufacturers can navigate challenges, capitalize on opportunities, and shape a future where products are not only functional and desirable but also ethical, sustainable, and inclusive. As we embark on this journey of manufacturing excellence, let us strive to create a world where quality products enrich lives, empower communities, and inspire generations to come.