Product manufacturing is a complex yet essential process that transforms raw materials or components into finished goods ready for consumption or use. This article explores the intricacies of product manufacturing, highlighting its stages, challenges, innovations, and its critical role in meeting consumer demands and driving economic growth.

1. Conceptualization and Design

Product manufacturing begins with conceptualization and design, where ideas are transformed into tangible products. This stage involves market research, identifying consumer needs, and conceptualizing product features and specifications. Designers, engineers, and product developers collaborate to create detailed plans using computer-aided design (CAD) software. Prototypes are often created and tested to validate functionality, aesthetics, and performance before moving to production.

2. Material Sourcing and Supply Chain Management

Once the design is finalized, manufacturers source raw materials and components from suppliers. Effective supply chain management ensures timely delivery, quality control, and cost efficiency. Materials may be sourced locally or globally, considering factors such as cost, quality, availability, and sustainability. Transparent communication and collaboration with suppliers are crucial to maintaining a reliable supply chain.

3. Manufacturing Processes

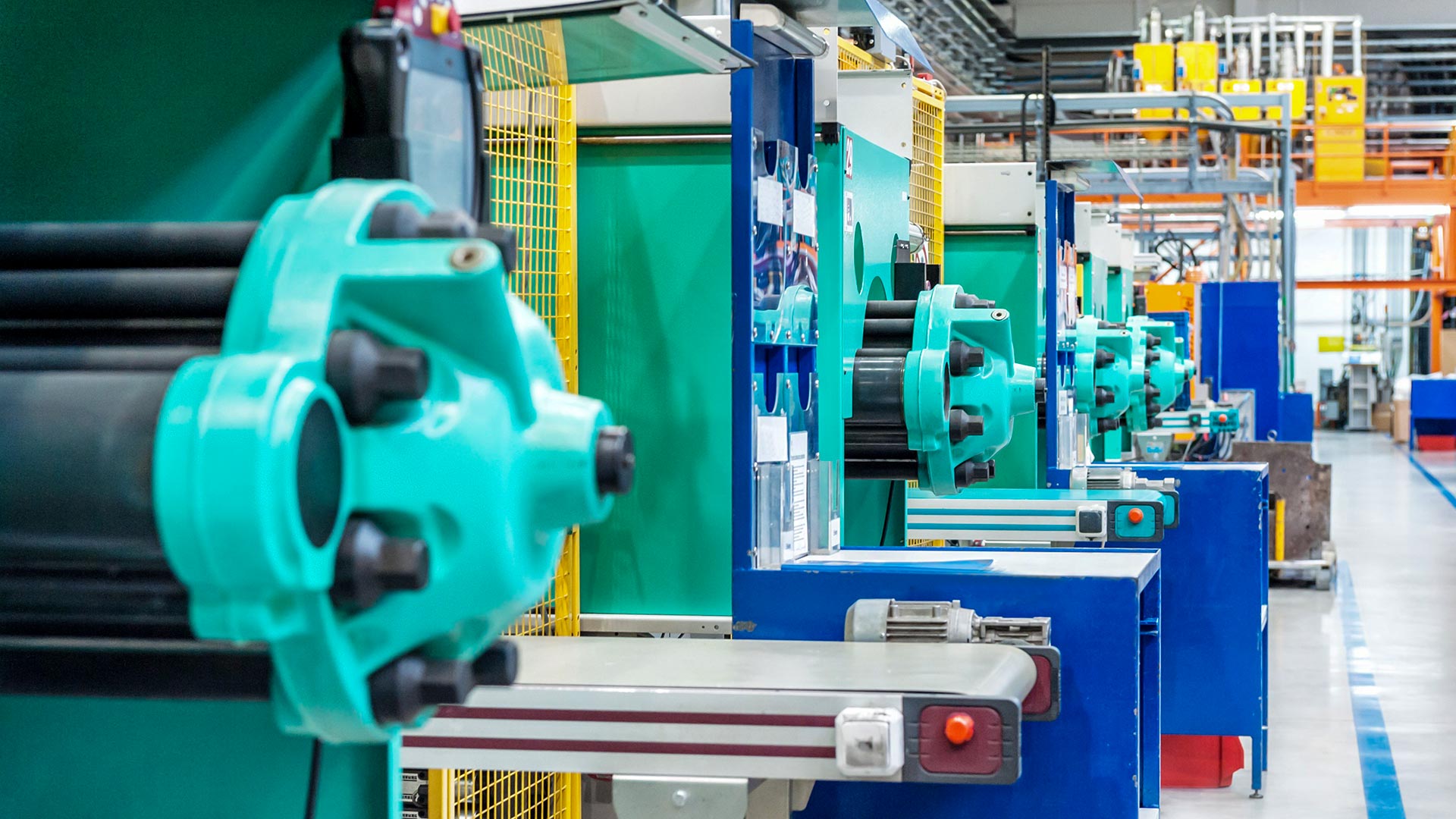

Manufacturing processes vary based on product complexity, industry standards, and technological advancements. Common manufacturing methods include:

- Assembly Line Production: Suitable for high-volume products, where components are assembled sequentially along a conveyor belt.

- Batch Production: Involves manufacturing specific quantities of products in batches, balancing efficiency with customization capabilities.

- Custom Manufacturing: Tailored to individual customer specifications, prevalent in industries requiring unique configurations or high precision.

Technological innovations such as robotics, automation, and advanced machinery enhance manufacturing efficiency, precision, and scalability. Continuous improvement methodologies like Lean manufacturing and Six Sigma optimize processes to minimize waste and maximize productivity.

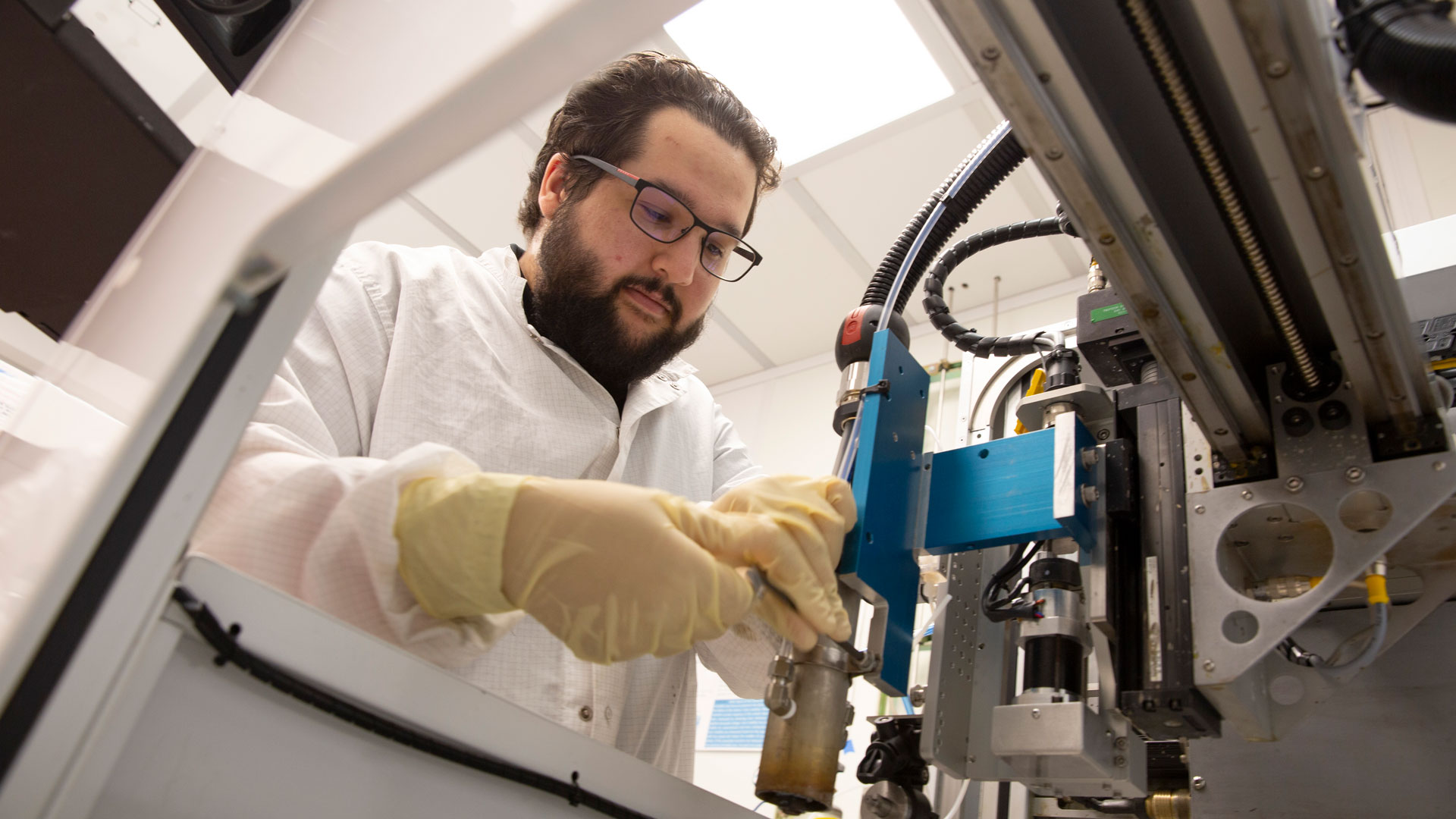

4. Quality Assurance and Control

Quality assurance (QA) and quality control (QC) are critical throughout the manufacturing process to ensure products meet stringent standards and customer expectations. QA involves establishing protocols and standards to prevent defects, while QC involves rigorous testing and inspection at various stages of production. Advanced testing techniques, statistical analysis, and adherence to regulatory requirements ensure consistency and reliability in product quality.

5. Packaging and Logistics

Packaging serves multiple functions beyond protection, including branding, product differentiation, and compliance with regulatory requirements. Efficient logistics management coordinates transportation, warehousing, and distribution to deliver products to consumers or retail outlets efficiently. Just-in-time (JIT) logistics strategies minimize inventory costs while maximizing responsiveness to market demand fluctuations.

6. Environmental Sustainability

Increasingly, manufacturers prioritize environmental sustainability throughout the product lifecycle. This includes using eco-friendly materials, optimizing energy consumption, reducing waste generation, and implementing recycling and circular economy practices. Sustainable manufacturing practices not only mitigate environmental impact but also enhance brand reputation and appeal to environmentally conscious consumers.

Challenges in Product Manufacturing

Product manufacturing faces several challenges that impact efficiency, cost, and market competitiveness:

- Global Competition: Pressure from low-cost producers in emerging markets requires manufacturers to innovate continuously and optimize production costs.

- Supply Chain Disruptions: Global supply chain disruptions, natural disasters, and geopolitical uncertainties can disrupt production schedules and increase operational risks.

- Regulatory Compliance: Compliance with local and international regulations, safety standards, and environmental laws adds complexity and costs to manufacturing operations.

Future Trends in Product Manufacturing

The future of product manufacturing is shaped by emerging trends and technologies:

- Industry 4.0: Integration of IoT, AI, big data analytics, and cloud computing to create smart factories that optimize production processes, enable predictive maintenance, and enhance decision-making capabilities.

- Customization and Personalization: Growing consumer demand for customized products drives the adoption of flexible manufacturing systems and advanced technologies like 3D printing for on-demand production.

- Sustainable Practices: Increasing emphasis on sustainable manufacturing practices, including renewable energy use, waste reduction, and closed-loop supply chains to minimize environmental impact and enhance corporate social responsibility (CSR).

Conclusion

In conclusion, product manufacturing is a dynamic and multifaceted process essential to producing goods that meet consumer needs and drive economic growth. From conceptualization and design to final production and distribution, manufacturers navigate challenges while embracing technological advancements and sustainable practices. By prioritizing innovation, quality assurance, and efficient supply chain management, manufacturers can meet market demands, maintain competitive advantage, and contribute to a sustainable future for industries worldwide. Product manufacturing remains a cornerstone of industrial development, innovation, and global trade, shaping economies and improving standards of living across diverse markets.