Product manufacturing companies play a pivotal role in bringing ideas to life, transforming raw materials into finished goods that meet consumer needs and demands. These companies operate across various industries, from automotive and electronics to consumer goods and pharmaceuticals, driving economic growth and technological innovation. This article explores the intricacies of product manufacturing companies, their core functions, challenges, and strategies for success in today’s competitive market.

Core Functions of Product Manufacturing Companies

- Product Development and Design: Product manufacturing companies begin their journey with the conception and design of new products. This involves research, innovation, and collaboration between engineers, designers, and product developers to create prototypes and finalize product specifications.

- Sourcing and Procurement: Once the product design is finalized, manufacturing companies source raw materials, components, and resources required for production. This involves establishing supplier relationships, negotiating contracts, and ensuring timely delivery of materials to meet production schedules.

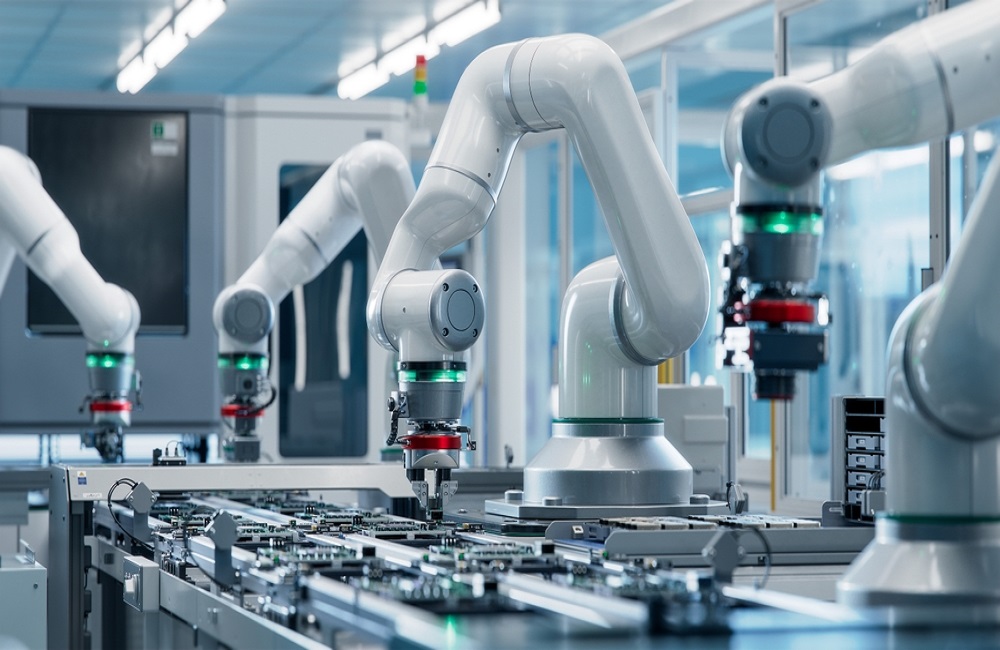

- Production and Assembly: Production and assembly are the heart of manufacturing operations, where raw materials are transformed into finished goods. This phase involves a range of processes, including machining, molding, welding, and assembly, to manufacture products efficiently and cost-effectively.

- Quality Assurance and Control: Maintaining high product quality is paramount for manufacturing companies to uphold customer satisfaction and brand reputation. Quality assurance and control involve implementing standards, inspections, and testing procedures to ensure that products meet stringent quality requirements.

- Logistics and Distribution: Once products are manufactured, manufacturing companies manage logistics and distribution to deliver finished goods to customers. This involves transportation, warehousing, inventory management, and order fulfillment to ensure timely delivery and customer satisfaction.

Challenges Facing Product Manufacturing Companies

- Global Competition: Product manufacturing companies face intense competition from both domestic and international rivals, driving the need for innovation, efficiency, and cost competitiveness to stay ahead in the market.

- Supply Chain Disruptions: Global supply chains are vulnerable to disruptions, such as natural disasters, geopolitical tensions, and trade disputes, which can impact the availability and cost of raw materials and components.

- Regulatory Compliance: Manufacturing companies must comply with a myriad of regulations and standards related to product safety, environmental protection, and labor practices, which can vary across different regions and industries.

- Technology Adoption: Rapid technological advancements, such as automation, robotics, and digitalization, require manufacturing companies to continuously invest in upgrading their technology infrastructure and workforce skills to remain competitive.

- Sustainability and Environmental Concerns: With growing concerns over climate change and environmental degradation, manufacturing companies are under pressure to adopt sustainable practices, reduce carbon emissions, and minimize waste throughout the product lifecycle.

Strategies for Success

- Innovation and R&D Investment: Manufacturing companies must prioritize innovation and invest in research and development (R&D) to create differentiated products, improve processes, and stay ahead of market trends.

- Efficiency and Lean Manufacturing: Adopting lean manufacturing principles and continuous improvement methodologies can help manufacturing companies streamline operations, reduce waste, and enhance productivity.

- Supply Chain Resilience: Building resilient supply chains with diversified sourcing strategies, supplier partnerships, and risk mitigation plans can help manufacturing companies mitigate supply chain disruptions and ensure business continuity.

- Digital Transformation: Embracing digital technologies, such as data analytics, IoT, and cloud computing, can enable manufacturing companies to optimize operations, improve decision-making, and enhance customer engagement.

- Sustainability and Corporate Social Responsibility (CSR): Integrating sustainability into business practices and CSR initiatives can enhance brand reputation, attract environmentally conscious consumers, and create long-term value for stakeholders.

Case Studies of Successful Product Manufacturing Companies

- Tesla, Inc.: Tesla revolutionized the automotive industry with its electric vehicles and renewable energy solutions. By focusing on innovation, sustainability, and vertical integration, Tesla has become a leader in electric vehicle manufacturing and clean energy technology.

- Apple Inc.: Apple is renowned for its iconic products, such as the iPhone, iPad, and Macintosh computers. Through a combination of design excellence, supply chain efficiency, and customer-centric approach, Apple has achieved unparalleled success in the consumer electronics market.

- Procter & Gamble (P&G): P&G is a multinational consumer goods company known for brands such as Gillette, Pampers, and Tide. With a focus on product innovation, brand management, and global supply chain management, P&G has maintained its position as a market leader in the fast-moving consumer goods industry.

Conclusion

Product manufacturing companies play a vital role in driving economic growth, technological innovation, and societal progress. By embracing innovation, efficiency, and sustainability, manufacturing companies can navigate the challenges of global competition, supply chain disruptions, and regulatory complexities to thrive in today’s dynamic business environment. Through strategic investments, collaboration, and a commitment to excellence, manufacturing companies can continue to deliver high-quality products that meet the evolving needs of consumers worldwide.