Manufacturing is a cornerstone of economic development, providing essential goods and creating employment opportunities across various sectors. From automotive and aerospace to electronics and consumer goods, manufacturing processes drive innovation, efficiency, and productivity. This article highlights examples of manufacturing excellence across different industries, showcasing innovative approaches, cutting-edge technologies, and impactful outcomes.

Automotive Manufacturing: Tesla, Inc.

Tesla, Inc. stands out as a prime example of manufacturing excellence in the automotive industry. Known for its electric vehicles (EVs) and sustainable energy solutions, Tesla has redefined the automotive landscape with its innovative approach to design, production, and technology. By vertically integrating its manufacturing operations, Tesla controls the entire production process, from battery production to vehicle assembly, enabling greater efficiency and quality control. The company’s Gigafactories, strategically located around the world, leverage advanced robotics, automation, and renewable energy sources to scale production and reduce environmental impact. Tesla’s focus on innovation, sustainability, and customer experience has propelled it to the forefront of the EV market and positioned it as a leader in automotive manufacturing.

Aerospace Manufacturing: Airbus SE

Airbus SE exemplifies manufacturing excellence in the aerospace industry, known for its cutting-edge aircraft designs, technological innovations, and global reach. As one of the world’s leading aircraft manufacturers, Airbus designs, develops, and manufactures commercial aircraft, helicopters, and defense systems for customers worldwide. Airbus’ state-of-the-art manufacturing facilities, such as the Airbus A320 Final Assembly Line in Hamburg, Germany, and the Airbus A350 XWB Final Assembly Line in Toulouse, France, showcase advanced manufacturing processes, digitalization, and automation. By leveraging digital twin technology, robotics, and additive manufacturing, Airbus streamlines production, enhances precision, and accelerates time-to-market for its aircraft. Airbus’ commitment to innovation, safety, and sustainability has solidified its position as a premier player in the aerospace manufacturing industry.

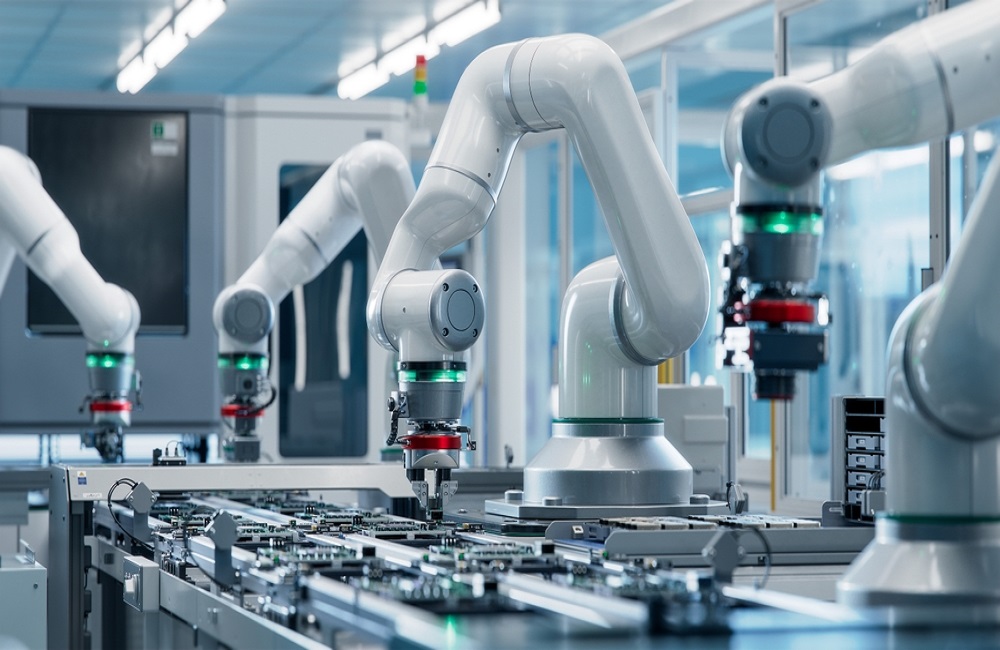

Electronics Manufacturing: Samsung Electronics Co., Ltd.

Samsung Electronics Co., Ltd. is a global leader in electronics manufacturing, renowned for its diverse portfolio of consumer electronics, semiconductors, and display technologies. With manufacturing facilities spanning the globe, Samsung delivers innovative products that enrich people’s lives and drive technological progress. Samsung’s semiconductor division, for example, leads the industry in the development and production of advanced semiconductor chips used in smartphones, computers, and IoT devices. The company’s manufacturing prowess is evident in its cutting-edge semiconductor fabs, such as the Samsung Semiconductor Complex in Pyeongtaek, South Korea, which features advanced cleanroom facilities and state-of-the-art equipment. Samsung’s commitment to quality, reliability, and continuous innovation has cemented its reputation as a trailblazer in the electronics manufacturing sector.

Consumer Goods Manufacturing: Procter & Gamble (P&G)

Procter & Gamble (P&G) is a global leader in consumer goods manufacturing, known for its iconic brands, product innovation, and supply chain excellence. P&G’s diverse portfolio of household and personal care products, including Tide, Pampers, and Gillette, are household names trusted by consumers worldwide. P&G’s manufacturing operations encompass a vast network of facilities located across continents, equipped with advanced production technologies and stringent quality control measures. The company’s commitment to sustainability is reflected in its sustainability goals, such as reducing greenhouse gas emissions, conserving water, and minimizing waste throughout the product lifecycle. P&G’s relentless focus on consumer needs, innovation, and sustainability has propelled it to the forefront of consumer goods manufacturing and established it as a leader in the industry.

Conclusion

These examples of manufacturing excellence underscore the diverse range of industries and the transformative impact of manufacturing on global economies and societies. Whether it’s automotive, aerospace, electronics, or consumer goods, manufacturing companies demonstrate innovation, efficiency, and resilience in their pursuit of excellence. By embracing advanced technologies, sustainable practices, and customer-centric approaches, these manufacturers drive innovation, create value, and shape the future of manufacturing across the globe.