Manufacturing stands as a cornerstone of economic development, encompassing the process of transforming raw materials or components into finished goods through various production methods and techniques. In this article, we delve into the meaning, significance, and impact of manufacturing on economies, industries, and societies worldwide.

Defining Manufacturing

At its essence, manufacturing involves the conversion of inputs, including raw materials, components, and labor, into tangible products that hold value for consumers or other businesses. This transformation process typically occurs in facilities such as factories, plants, or workshops, where machinery, equipment, and skilled labor are employed to produce goods at scale.

The Significance of Manufacturing

Manufacturing plays a pivotal role in driving economic growth, employment generation, and technological innovation across nations. Its significance extends beyond the production of goods to encompass various aspects of economic development and societal well-being.

1. Economic Growth: Manufacturing contributes significantly to gross domestic product (GDP) in many countries, serving as a primary driver of economic growth and prosperity. It stimulates demand for raw materials, machinery, and services, thereby creating a multiplier effect that boosts economic activity across sectors.

2. Job Creation: Manufacturing sectors are major employers, providing livelihoods for millions of people worldwide. From skilled technicians and engineers to assembly line workers and logistics personnel, manufacturing creates diverse employment opportunities, particularly in regions with established industrial bases.

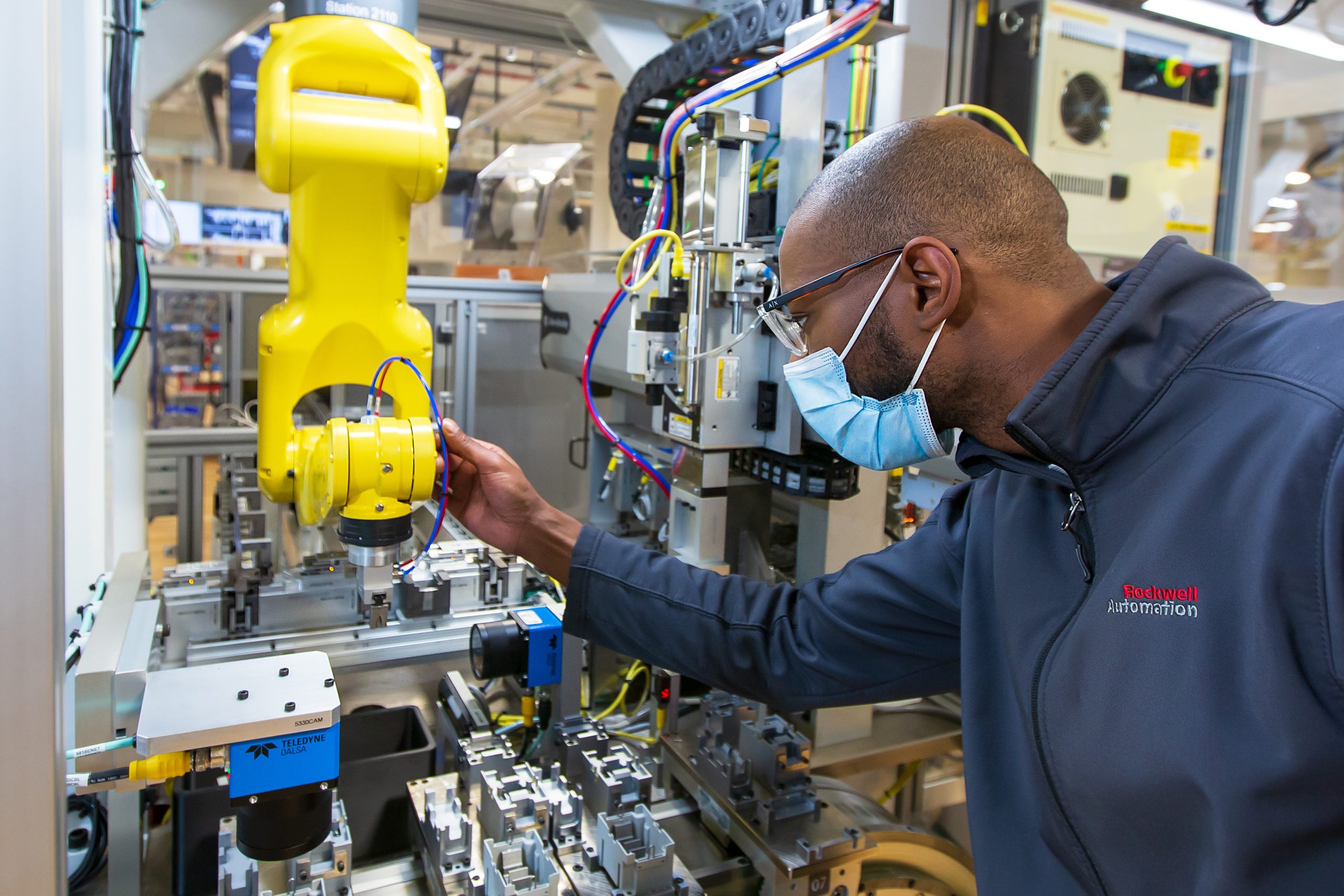

3. Technological Innovation: Manufacturing fosters technological innovation and advancements by driving research and development activities, fostering collaboration between academia and industry, and promoting the adoption of cutting-edge technologies. Innovations in manufacturing processes, materials, and products often have ripple effects across other sectors, spurring further innovation and competitiveness.

4. Global Trade: Manufacturing fuels international trade by facilitating the exchange of goods and services between nations. Countries with strong manufacturing capabilities often leverage their comparative advantages to export a wide range of products, contributing to trade balances and fostering economic interdependence.

5. Infrastructure Development: The presence of robust manufacturing sectors spurs investments in infrastructure such as transportation networks, energy systems, and telecommunications, creating a conducive environment for economic development and industrial growth.

Challenges and Opportunities

Despite its significance, manufacturing faces various challenges in an increasingly globalized and competitive landscape. These challenges include rising production costs, supply chain disruptions, technological disruptions, and environmental sustainability concerns. However, they also present opportunities for innovation, collaboration, and adaptation.

1. Automation and Digitalization: The adoption of automation, robotics, and digital technologies is transforming traditional manufacturing processes, enabling higher productivity, flexibility, and customization. Embracing Industry 4.0 principles can help manufacturers stay agile and competitive in the digital age.

2. Sustainable Manufacturing: Addressing environmental sustainability concerns is imperative for the long-term viability of manufacturing. Adopting eco-friendly practices, optimizing resource utilization, and embracing circular economy principles can help reduce environmental impact while enhancing efficiency and competitiveness.

Conclusion

Manufacturing remains a fundamental pillar of economic development, driving growth, innovation, and prosperity across nations. Its significance transcends mere production, encompassing job creation, technological advancement, and infrastructure development. As manufacturers navigate through evolving challenges and opportunities, embracing innovation, sustainability, and collaboration will be key to shaping a resilient and prosperous future for the manufacturing sector and the global economy as a whole.