Although steel has been produced for over 100 years in plants across the United States, there are tricks of the industry that have been discovered and used during the process as the technology continues to evolve and modernize. Here are a few of the many things that humankind has discovered about iron and steel as they continue to create the products that you use every day.

Iron

There are different strengths and purities of metals that are created out of different combinations of ores. There are ferrous metals that contain iron, and non-ferrous metals that contain no iron or have had the iron removed. It was learned early on that while the ferrous metals could be used to make a variety of products such as aluminum and magnesium, only the non-ferrous metals could be employed to create the exceptional strength of steel.

Coke

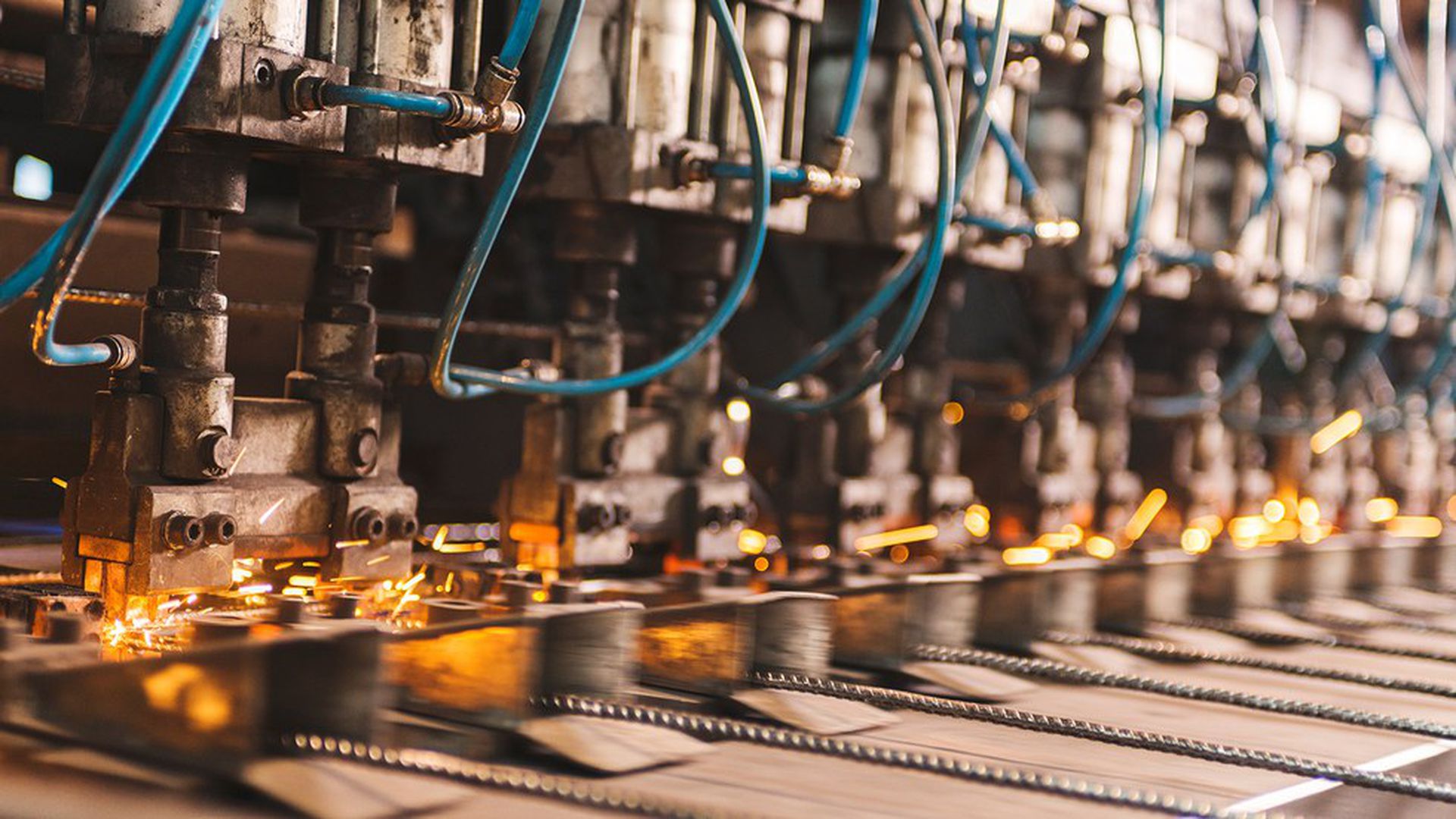

Coal has been used in the production of steel since the beginning. But to create the type of coal needed to burn hot enough to produce steel, the coal had to be impurity free. Once the coal was iron-free, it became known as coke. To remove iron from the huge amount of coal needed to make the steel, the coke oven was created. The oven is a big cavern and the iron filled coal was put into the massive structure and burned at extremely high temperatures in the ‘blast furnace.’ These huge ovens have been modified, but they are still used today, and to protect workers, these furnaces must have specialized protective coke oven doors.

Furnace

When creating steel, temperatures inside the furnace are over 3,000 Fahrenheit. The extreme heat allows residual iron to make its way to the bottom of the furnace, collecting all the impurities as it does. The coke slag floats on top of the iron and can then be drained out of a tap hole.

No, iron and steel don’t mix. You can be glad that humankind found that out over 100 years ago, or many of the things you use every day would only exist in your imagination.