Product manufacturing is a multifaceted process that transforms raw materials and components into finished goods ready for distribution and sale. From the initial design phase to the final assembly line, each step in the manufacturing process plays a crucial role in delivering high-quality products to consumers. In this article, we’ll explore the intricacies of product manufacturing, from concept to consumer, highlighting key stages, considerations, and best practices along the way.

1. Conceptualization and Design

The journey of product manufacturing begins with conceptualization and design, where ideas are transformed into tangible concepts and blueprints. This phase involves market research, brainstorming, and collaboration among designers, engineers, and stakeholders to define product specifications, features, and aesthetics. Designers utilize computer-aided design (CAD) software to create detailed 2D and 3D models, prototypes, and mock-ups, iterating and refining designs based on feedback and testing.

2. Material Sourcing and Procurement

Once the design is finalized, the next step is material sourcing and procurement, where raw materials, components, and parts are sourced from suppliers and vendors. Manufacturers must consider factors such as cost, quality, lead times, and supply chain reliability when selecting materials and suppliers. Strategic partnerships, long-term contracts, and supplier audits help ensure a steady supply of high-quality materials and components for production.

3. Production Planning and Scheduling

Production planning and scheduling involve coordinating manufacturing processes, resources, and timelines to meet production targets and customer demand. Manufacturers utilize production planning software and enterprise resource planning (ERP) systems to optimize production schedules, allocate resources, and manage inventory levels efficiently. Factors such as production capacity, lead times, labor availability, and machine utilization are taken into account when planning and scheduling production activities.

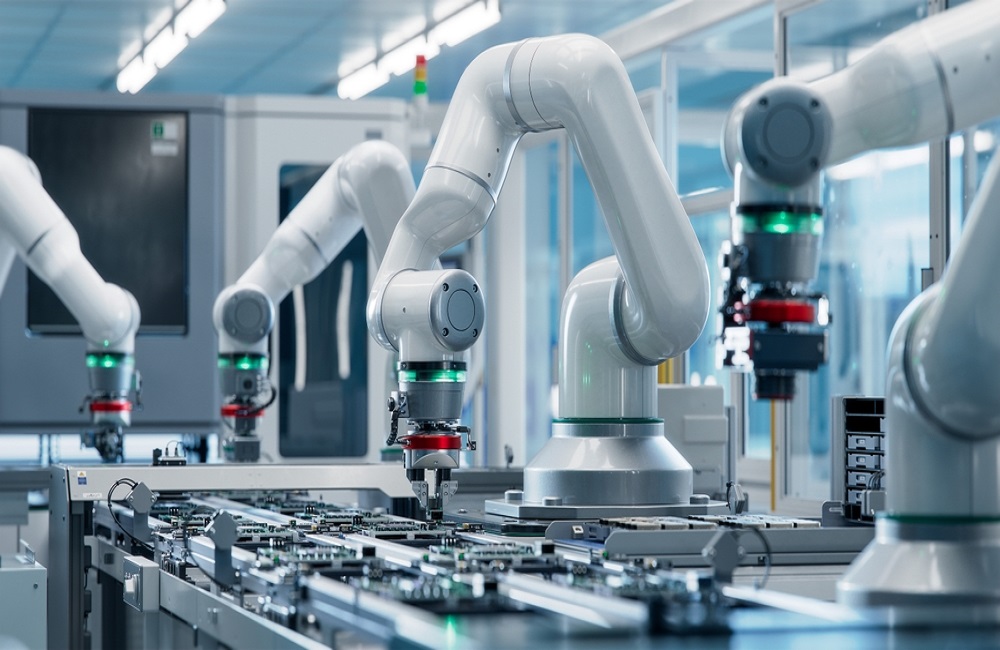

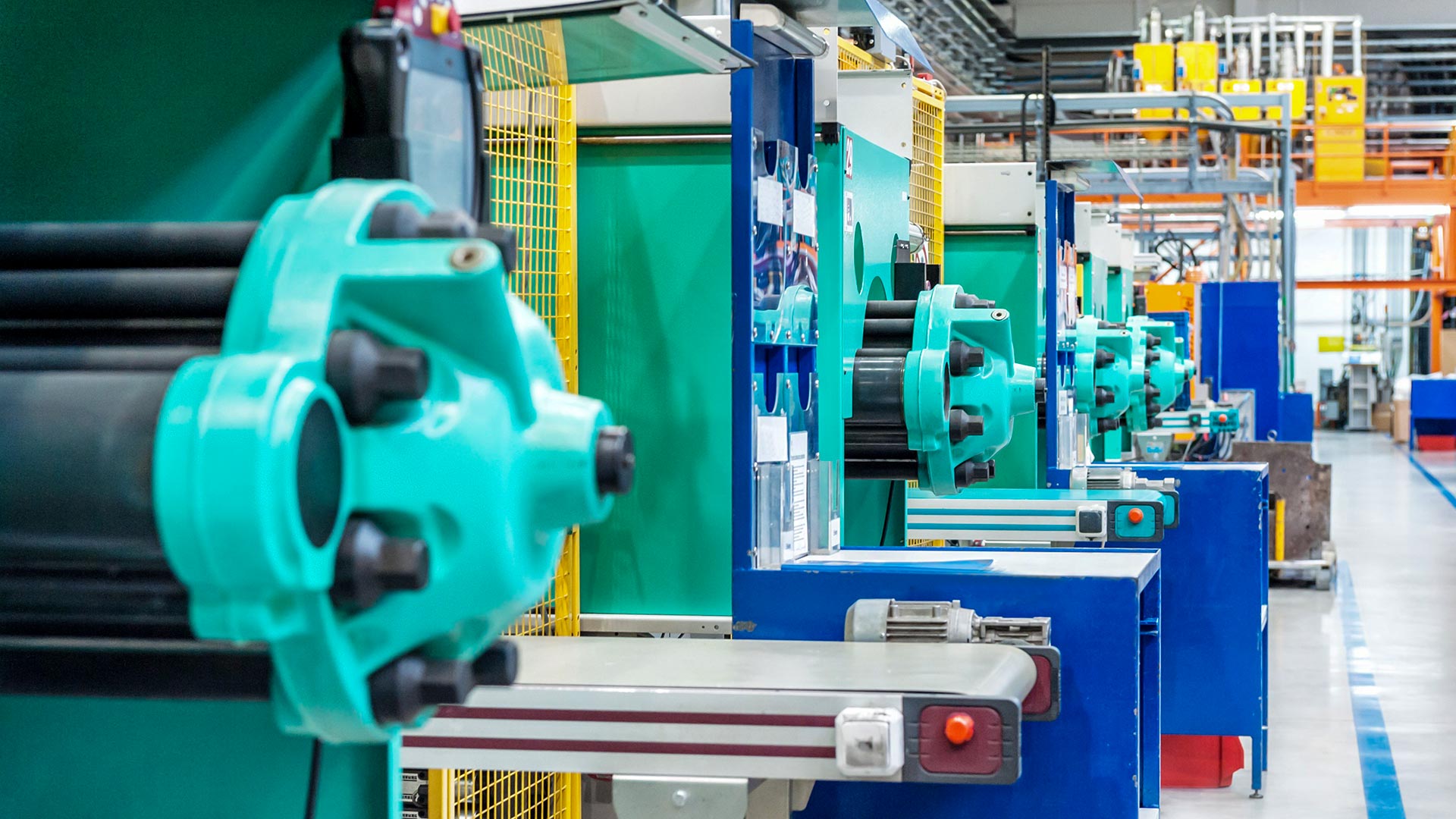

4. Manufacturing Processes

Manufacturing processes encompass a wide range of activities, techniques, and technologies used to transform raw materials into finished products. Depending on the nature of the product and industry, manufacturing processes may include:

- Machining: Cutting, drilling, milling, and shaping raw materials using machine tools such as lathes, milling machines, and CNC (computer numerical control) machines.

- Forming: Shaping and bending materials into desired shapes and configurations using processes such as forging, casting, stamping, and molding.

- Assembly: Joining and assembling components, parts, and subassemblies to create finished products using techniques such as welding, soldering, adhesives, and fasteners.

- Finishing: Surface treatment and finishing processes such as painting, coating, plating, polishing, and sanding to enhance appearance, durability, and functionality.

- Quality Control: Inspection, testing, and quality assurance processes to ensure that products meet specifications, standards, and regulatory requirements.

5. Quality Assurance and Testing

Quality assurance and testing are critical aspects of product manufacturing, ensuring that products meet quality standards, specifications, and customer expectations. Manufacturers employ quality control inspectors, testing laboratories, and quality management systems to monitor and evaluate product quality throughout the manufacturing process. Testing methods may include dimensional inspection, material testing, performance testing, and reliability testing to identify defects, deviations, and non-conformities.

6. Packaging and Labeling

Packaging and labeling play a crucial role in product manufacturing, protecting products during storage, transportation, and distribution, as well as conveying important information to consumers. Packaging materials, designs, and labeling must comply with regulatory requirements, industry standards, and consumer preferences. Manufacturers utilize packaging design software, packaging automation equipment, and printing technologies to create attractive, functional, and compliant packaging solutions for their products.

7. Distribution and Logistics

Once products are manufactured and packaged, they are ready for distribution and delivery to customers. Distribution and logistics involve planning, coordinating, and managing the movement of products from manufacturing facilities to warehouses, distribution centers, retailers, and ultimately to end consumers. Manufacturers utilize transportation networks, logistics providers, and supply chain management systems to optimize distribution routes, minimize transit times, and reduce transportation costs.

8. Customer Service and Support

Customer service and support are integral components of the product manufacturing process, ensuring customer satisfaction, loyalty, and retention. Manufacturers provide pre-sales support, technical assistance, and after-sales service to address customer inquiries, resolve issues, and enhance the overall customer experience. Effective communication, responsive support channels, and continuous feedback mechanisms help build trust and loyalty with customers throughout their product ownership journey.

Conclusion

Product manufacturing is a complex and dynamic process that involves numerous stages, considerations, and stakeholders working together to bring products from concept to consumer. By leveraging advanced technologies, efficient processes, and strategic partnerships, manufacturers can optimize production, improve quality, and deliver innovative products that meet the evolving needs and expectations of consumers. As manufacturing continues to evolve in response to technological advancements and market trends, companies that embrace innovation, sustainability, and customer-centricity will be well-positioned to succeed in the competitive global marketplace.