Industrial products form the backbone of modern manufacturing, providing the essential components, machinery, and equipment necessary for various industries to function efficiently. In this article, we delve into the diverse world of industrial products, exploring their significance, innovation, and impact on global economies.

Understanding Industrial Products

Industrial products encompass a wide array of goods specifically designed for use in industrial applications. These products range from machinery and equipment to raw materials, tools, and components. They serve as the building blocks of manufacturing processes across sectors such as automotive, aerospace, construction, energy, and electronics.

Significance in Manufacturing

Industrial products play a pivotal role in driving efficiency, productivity, and quality within manufacturing operations. They enable businesses to automate processes, enhance precision, and scale production to meet market demands. From CNC machines and industrial robots to advanced materials and precision tools, industrial products empower manufacturers to innovate and stay competitive in a rapidly evolving landscape.

Innovation in Industrial Products

The realm of industrial products is characterized by continuous innovation aimed at improving performance, reliability, and sustainability. Advancements in materials science, engineering design, and manufacturing processes have led to the development of groundbreaking products with enhanced capabilities.

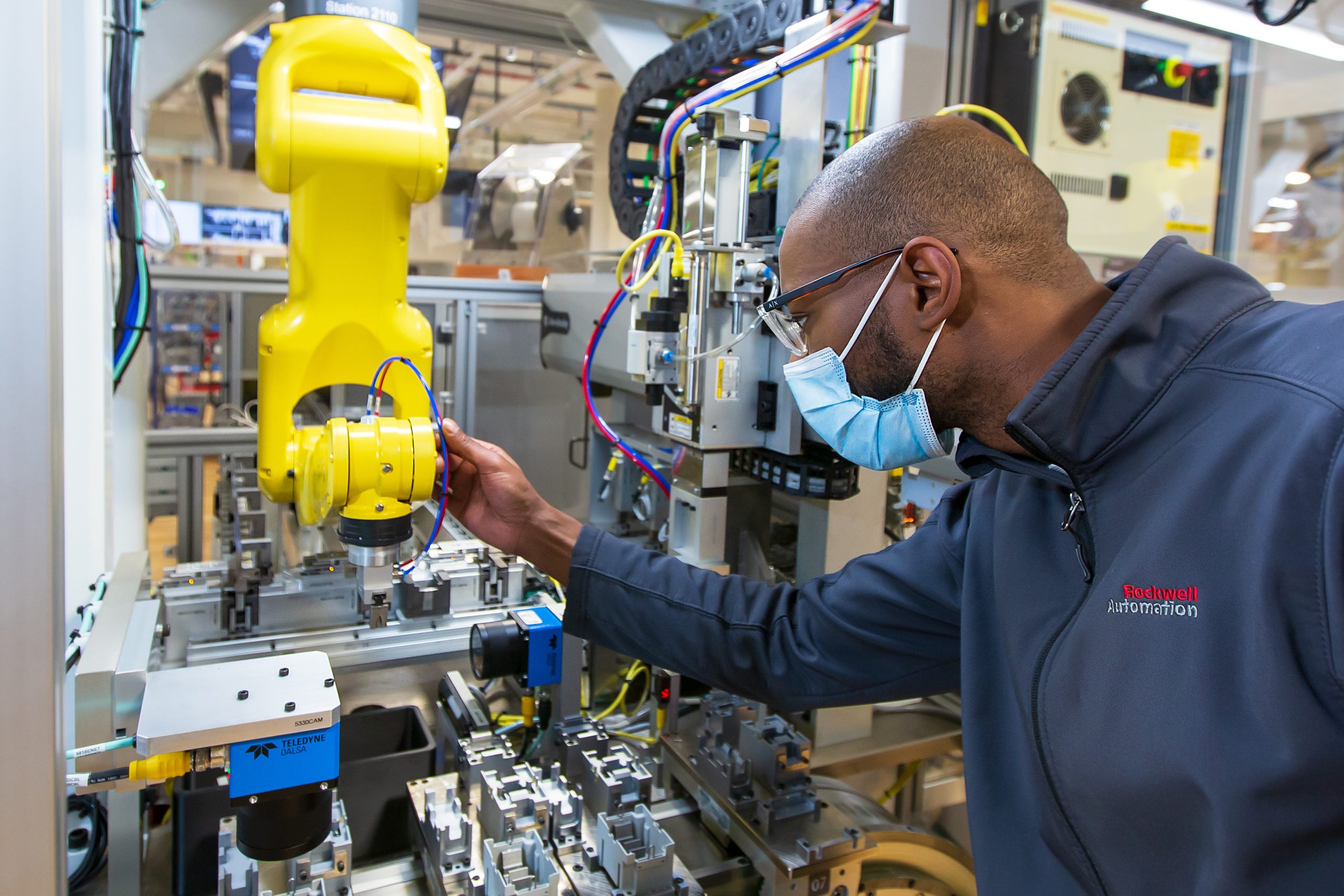

1. Advanced Machinery and Equipment: Industrial machinery and equipment have undergone significant advancements, leveraging technologies such as Internet of Things (IoT), artificial intelligence (AI), and additive manufacturing. Modern CNC machines, 3D printers, and robotic systems are revolutionizing production processes by offering unparalleled precision, flexibility, and efficiency.

2. Smart Technologies: The integration of smart technologies into industrial products has unlocked new levels of automation, connectivity, and data-driven insights. Smart sensors, actuators, and control systems enable real-time monitoring and optimization of equipment performance, predictive maintenance, and remote operation, leading to reduced downtime and improved resource utilization.

3. Sustainable Solutions: Sustainability has become a key focus in industrial product development, with manufacturers increasingly adopting eco-friendly materials, energy-efficient technologies, and circular economy principles. From recyclable materials and energy-efficient machinery to waste-reducing processes, industrial products are evolving to minimize environmental impact and promote sustainable practices.

Impact on Global Economies

The innovation and adoption of industrial products have far-reaching implications for global economies, driving growth, competitiveness, and technological advancement. Industrial products facilitate the efficient production of goods, enable the development of infrastructure, and support the expansion of key industries, contributing to job creation and economic prosperity.

Moreover, the export of industrial products fuels international trade, fostering economic interdependence and collaboration among nations. Countries with strong industrial sectors often emerge as leaders in global trade, leveraging their expertise to supply high-quality products to markets worldwide.

Conclusion

Industrial products represent the cornerstone of modern manufacturing, enabling businesses to innovate, optimize, and thrive in today’s dynamic market environment. From advanced machinery and smart technologies to sustainable solutions, the evolution of industrial products continues to drive efficiency, productivity, and sustainability across industries. As manufacturers embrace innovation and adapt to changing consumer demands, the role of industrial products in shaping the future of manufacturing remains pivotal, paving the way for a more efficient, connected, and sustainable world.