In today’s fast-paced digital landscape, the demand for efficient and reliable data centers has never been higher. As organizations strive to optimize their operations, a groundbreaking technology has emerged to transform how data centers are designed, monitored, and managed: the digital twin for data centers. This innovative approach allows for the creation of a virtual replica of physical data center assets, processes, and systems, facilitating real-time analysis and decision-making. Understanding the benefits and applications of digital twins in data centers is essential for organizations aiming to stay ahead of the curve in this ever-evolving industry.

Understanding Digital Twins in Data Centers

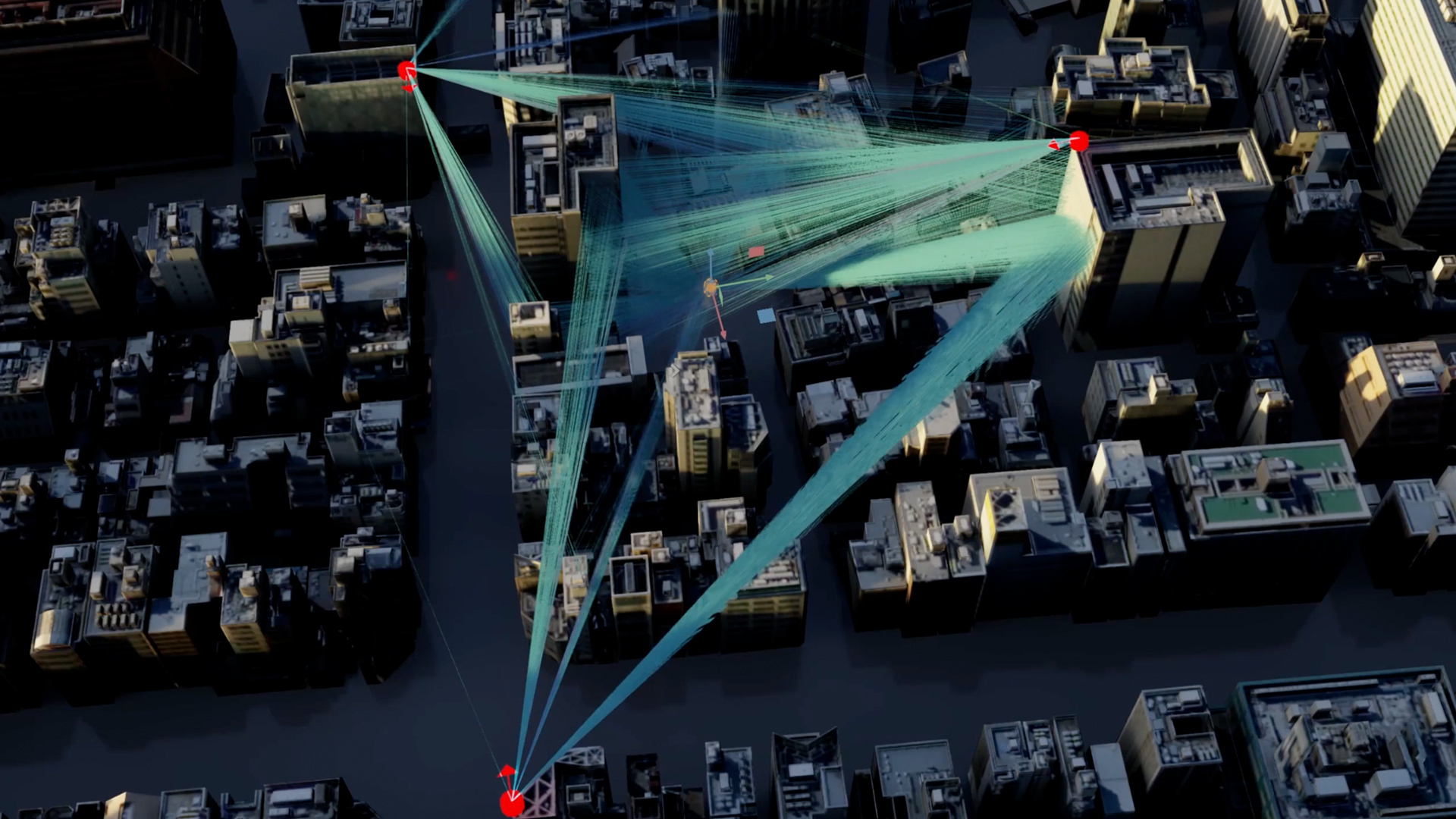

A digital twin for data centers serves as a dynamic virtual representation of physical systems, enabling organizations to simulate, analyze, and predict outcomes in real time. This technology integrates data from various sources, such as sensors and IoT devices, to create an accurate digital counterpart of the physical data center. By leveraging advanced analytics and machine learning, operators can gain invaluable insights into the performance and efficiency of their data center infrastructure.

The digital twin concept encompasses a wide array of applications, from monitoring energy consumption and optimizing cooling systems to predicting equipment failures and planning for capacity expansion. By enabling a holistic view of the data center environment, organizations can make informed decisions that enhance operational efficiency and drive cost savings.

Enhancing Operational Efficiency

One of the primary benefits of implementing a digital twin for data centers is the significant enhancement in operational efficiency. By providing real-time visibility into system performance, data center managers can identify inefficiencies and address them proactively. For instance, the digital twin can analyze energy usage patterns and recommend adjustments to reduce consumption during peak hours. This capability not only leads to cost savings but also contributes to sustainability efforts by minimizing the carbon footprint of data center operations.

Moreover, the ability to simulate various scenarios allows operators to evaluate the impact of potential changes without disrupting actual operations. For example, if a data center plans to introduce a new cooling system, the digital twin can model the anticipated performance, helping managers make data-driven decisions regarding implementation. This level of analysis is invaluable in preventing costly downtime and ensuring the seamless operation of critical infrastructure.

Predictive Maintenance and Reliability

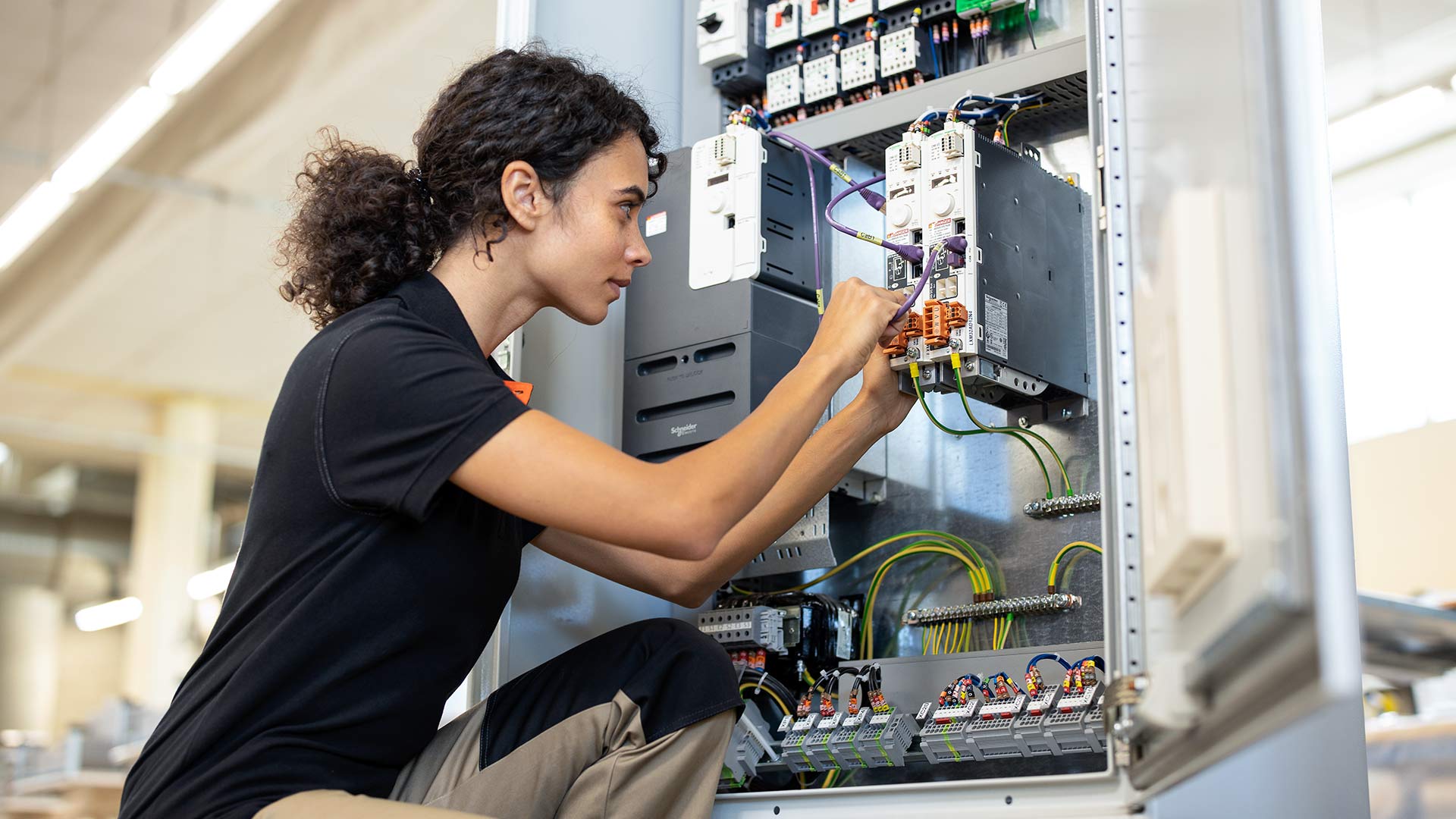

Another compelling application of the digital twin for data centers is predictive maintenance. By continuously monitoring equipment performance and utilizing machine learning algorithms, digital twins can identify patterns indicative of potential failures. This proactive approach enables organizations to schedule maintenance before equipment breakdowns occur, minimizing downtime and extending the lifespan of critical assets.

For instance, if the digital twin detects unusual vibrations in a server cooling unit, it can alert maintenance teams to investigate the issue before it escalates into a major problem. This predictive capability significantly enhances the reliability of data center operations, ensuring that services remain uninterrupted and meeting the increasing demands of customers.

Additionally, the digital twin can help optimize asset utilization by identifying underperforming equipment or systems. By analyzing historical performance data, organizations can make informed decisions regarding upgrades or replacements, ensuring that their data center operates at peak efficiency.

Driving Innovation through Simulation and Testing

The digital twin for data centers also plays a crucial role in driving innovation by enabling simulation and testing of new technologies and strategies. As organizations seek to implement cutting-edge solutions, such as artificial intelligence and advanced automation, the digital twin serves as a risk-free environment for experimentation.

For example, when considering the integration of a new cloud management system, data center operators can use the digital twin to simulate its performance within the existing infrastructure. This process allows them to assess potential challenges, evaluate resource allocation, and determine the most effective implementation strategy without the risk of disrupting ongoing operations.

Furthermore, the insights gained from simulations can guide decision-makers in optimizing data center layouts and configurations. By testing different scenarios, such as varying the placement of servers or adjusting cooling systems, organizations can achieve a more effective and efficient data center design tailored to their specific needs.

The emergence of the digital twin for data centers represents a significant advancement in the way organizations manage their data infrastructure. By leveraging this innovative technology, data center operators can enhance operational efficiency, improve reliability through predictive maintenance, and foster innovation through simulation and testing. As the digital landscape continues to evolve, embracing digital twins will become increasingly essential for organizations looking to optimize their data center performance and meet the growing demands of the market.

…