The term “offshore” generally refers to activities, structures, or areas that are located away from the coastline or in open waters. This encompasses a wide range of industries, from oil and gas exploration and production to renewable energy generation and marine research.

The Backbone of Energy: Offshore Oil and Gas

For decades, the offshore industry has been synonymous with oil and gas extraction. Advanced technologies have enabled the exploration and exploitation of hydrocarbon reserves located beneath the seabed, often in deepwater environments. This involves complex operations such as:

- Offshore Drilling: Utilizing specialized rigs and vessels to drill wells into the seabed to extract oil and gas.

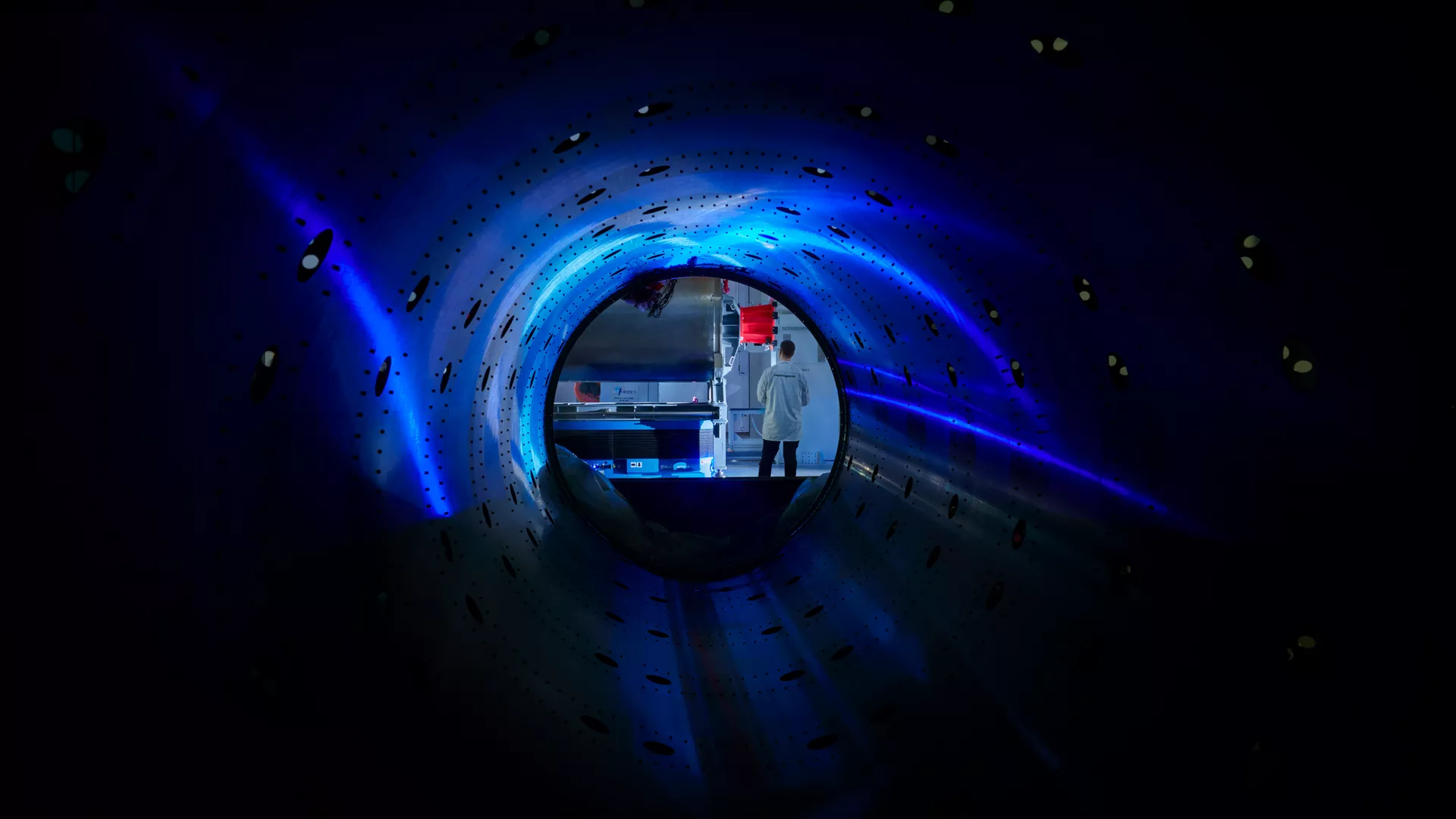

- Subsea Production: Installing and maintaining subsea equipment, including pipelines, manifolds, and control systems, to facilitate the flow of hydrocarbons from the seabed to surface facilities.

- Platform Construction and Maintenance: Building and maintaining offshore platforms, which serve as bases for drilling, production, and accommodation.

The Rise of Renewable Energy: Offshore Wind Power

In recent years, offshore wind power has emerged as a significant player in the renewable energy sector. Offshore wind farms harness the strong, consistent winds found at sea to generate electricity.

- Turbine Installation: Installing and maintaining large wind turbines on offshore foundations, often in deep water.

- Grid Connection: Connecting offshore wind farms to the onshore electricity grid through complex subsea cables.

- Environmental Considerations: Mitigating the environmental impact of offshore wind farms, including potential impacts on marine life and bird populations.

Beyond Oil and Gas: Other Offshore Activities

The offshore industry encompasses a diverse range of other activities, including:

- Marine Research: Conducting scientific research on marine ecosystems, oceanography, and climate change.

- Telecommunications: Laying and maintaining undersea cables for telecommunications and internet connectivity.

- Tourism and Recreation: Supporting offshore tourism activities, such as cruises, fishing, and diving.

Challenges and Opportunities in the Offshore Industry

The offshore industry faces a number of challenges, including:

- Environmental Risks: The potential for oil spills, pollution, and damage to marine ecosystems.

- Extreme Conditions: Operating in harsh and challenging environments, including strong currents, high winds, and deep waters.

- Technological Advancements: The need for continuous innovation and technological advancements to improve safety, efficiency, and environmental performance.

Despite these challenges, the offshore industry offers significant opportunities, particularly in the area of renewable energy. As the world transitions towards a low-carbon future, offshore wind power is poised to play a crucial role in meeting global energy demands.